How recycled nylon thread is made

Collect lint from within the mill.

Grind lint into chips.

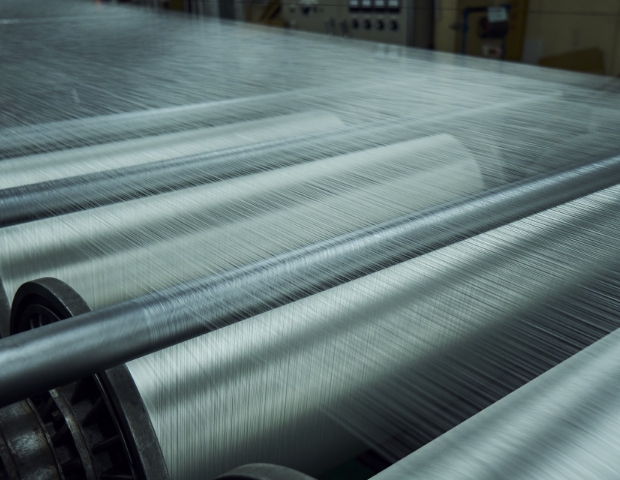

Melting the chips with heat and

extruding them into yarn.

Processing Technology 01

AIR

PROCESSING

TWISTED YARN

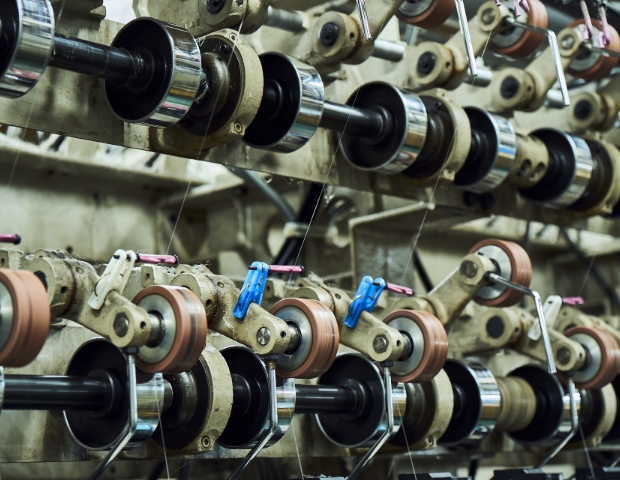

Advanced technology that makes

high-quality recycled nylon yarn feasible.

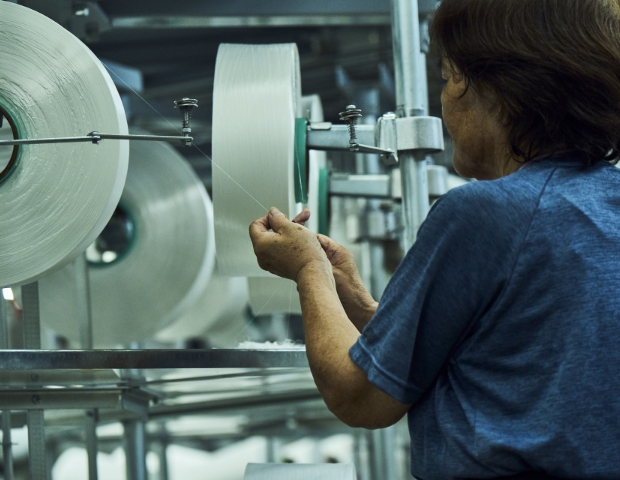

Air processing is a process in which multiple yarn are entangled like a single thread by the force of high-pressure air, and twisting yarn provides texture and strength through twining. In particular, mills with the know-how to twist sensitive yarn such as nylon are very rare to find. With our extensive equipment and accumulated knowledge and know-how, we are able to provide advanced manufacturing that is unrivaled in the industry.

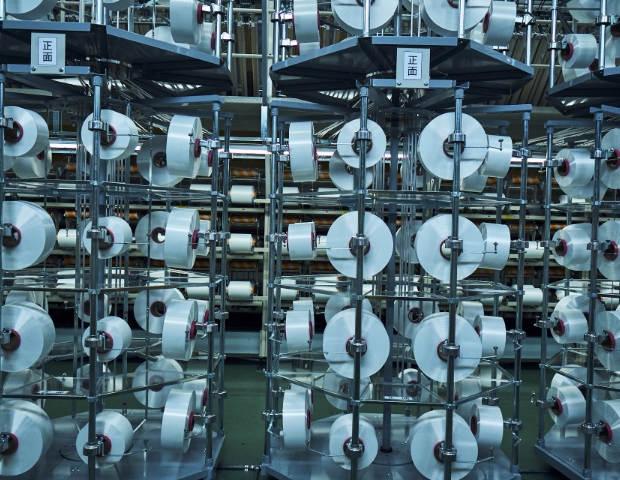

Processing Technology 02

FALSE

TWISTING

Cutting-edge machinery and excellent development

capabilities bring added value to yarn.

The technology of blended filament processing which blends yarn while draw texturizing process, makes it possible to produce yarn with added value and originality - for example, by giving synthetic fibers a texture closer to that of natural fibers. In terms of quality control, a thorough system has been established to prevent defective products by recording and tracking all data on each individual thread. For UNITO with the basic premise of being not only sustainable but also of high quality, these technologies are indispensable partners.

PRODUCTS

Products made with

UNITO nylon

for example…

raincoat

raincoat

lingerie

lingerie

bag

bag

Smooth to the touch, it features high water content and a moist feeling. Durable with a unique shine and luxurious feel, each product has a different appearance.