How recycled polyester thread is made

Collect and clean

used PET bottles.

Grind PET bottles

into chips.

Melting the chips with heat and

extruding them into yarn.

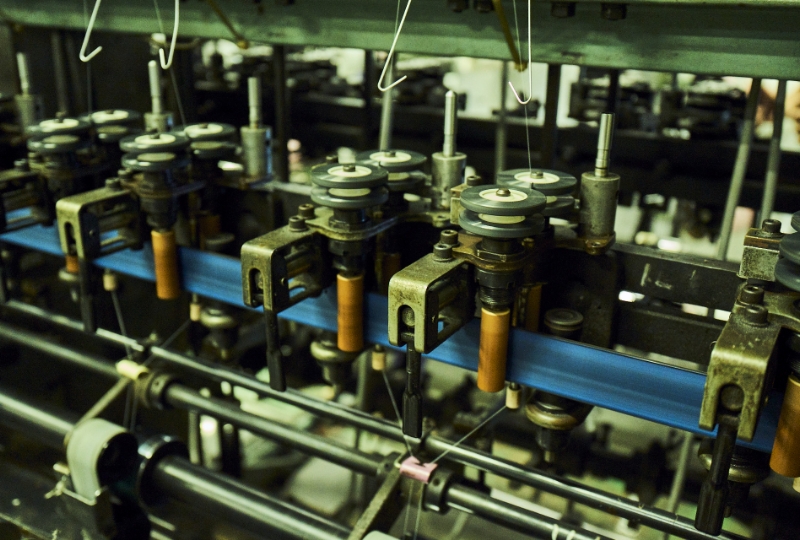

Processing Technology 01

FALSE

TWISTING

The unique texture that only a rare vintage

draw texturizing machine can deliver.

By using a low-speed draw texturizing machine, the yarn are slowly twisted and untwisted while being heated carefully, resulting in a highly crimped yarn that have a fluffy texture, elasticity, and stretchiness. It features a unique texture that only rare vintage machines - now handled by very few people - can produce, and is widely used not only for clothing but also for luxury car seats and other items.

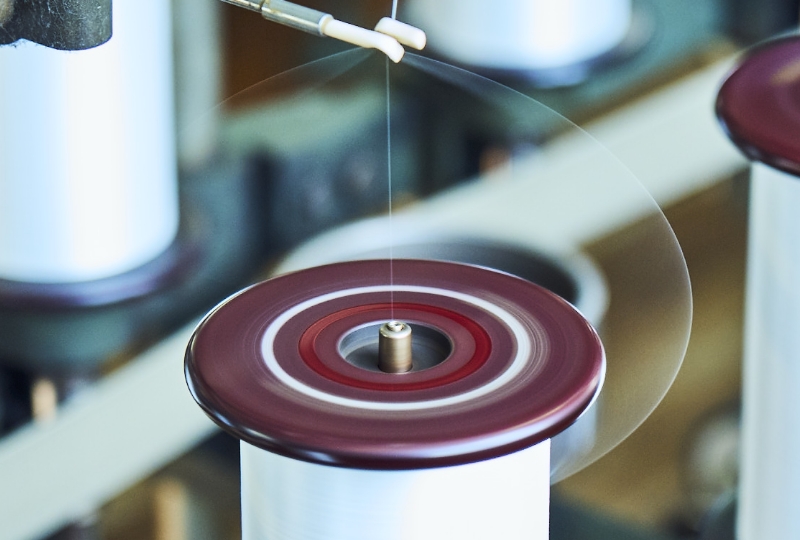

Processing Technology 02

COVERING

PROCESS

Stable supply of materials

Securement of large-scale mills

The covering process refers a process in which a sheath thread is wrapped around a core thread to make two yarn into one. The core thread is made of polyurethane stretching like rubber and covered with polyester or nylon to produce the thread. As polyurethane cannot be dyed, the covering process makes it possible to produce thread that is dyeable and highly elastic. Not only skilled techniques and knowledge, but also the earnest dedication of artisans to their craftsmanship are fully utilized in this process.

PRODUCTS

Products made with

UNITO polyester

for example…

car seat

car seat uniform

uniform fleece

fleecejacket

The soft and light touch of the fabric stands out with a sophisticated finish. Its distinctive drape and texture allow for the development of unique and appealing products.